Call Us: (302) 425-4400

TEST RESULTS

FUEL RIGHT BENCH TEST - SEE HOW WE STACK UP TO THE COMPETITION

ORIGINAL SAMPLE

Fuel Sample On Right Treated With Fuel Right

Fuel Sample On Right Treated With Fuel Right

24 HOURS

AFTER TREATMENT

AFTER TREATMENT

7 DAYS

AFTER TREATMENT

AFTER TREATMENT

21 DAYS

AFTER TREATMENT

AFTER TREATMENT

SEE THE RESULTS FOR YOURSELF!

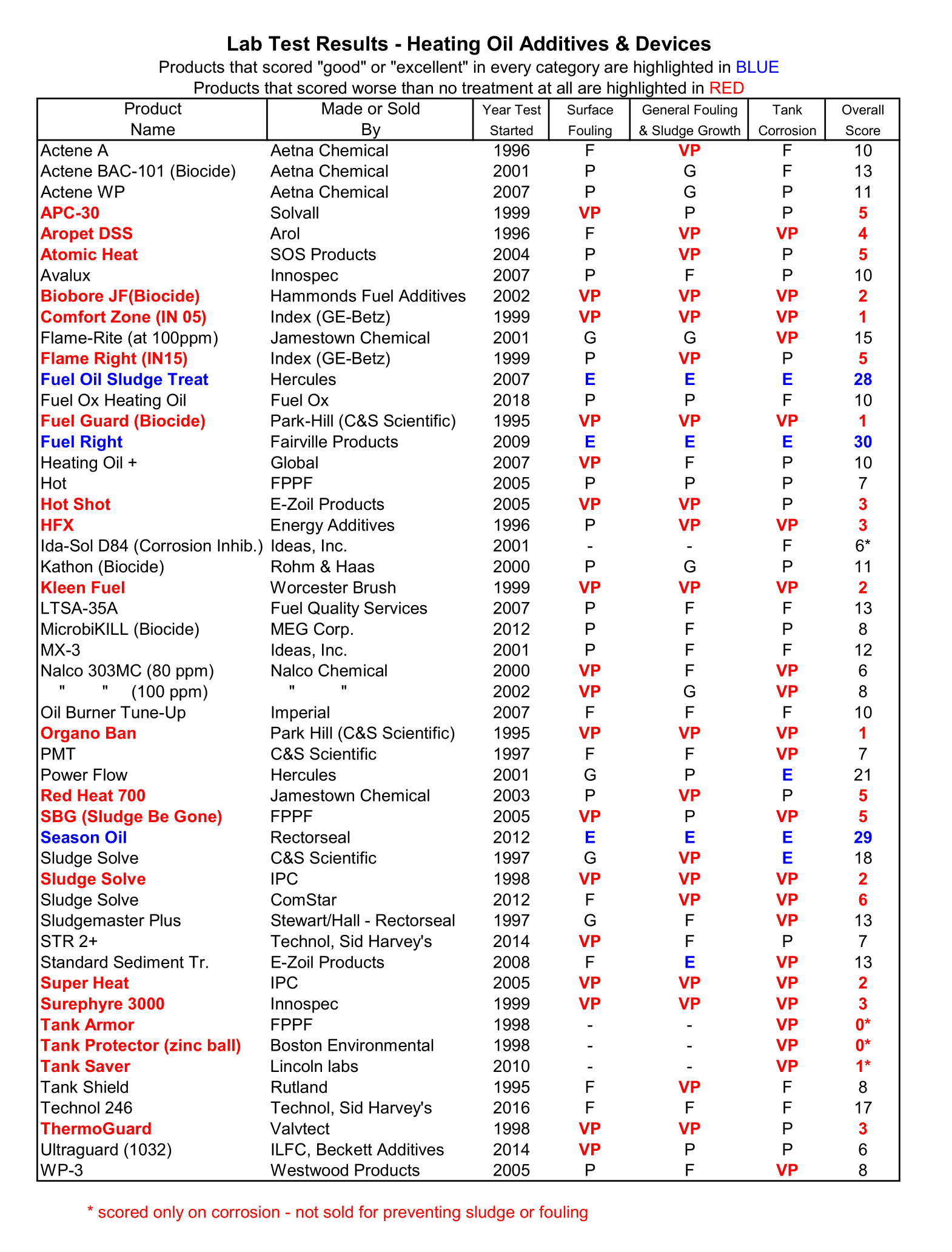

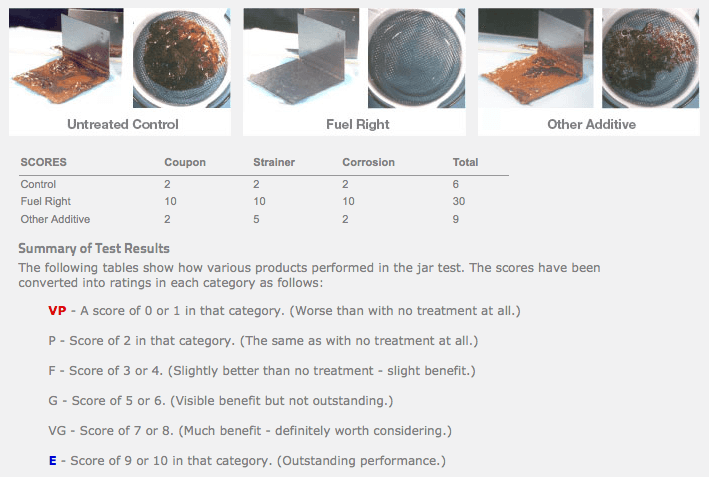

How It Works

Glass jars are filled with fuel oil or diesel fuel, a small amount of water, a steel panel or "coupon", and a small amount of sludge. One jar serves as the "control" and receives no additive. Each of the other jars is treated with an additive at the manufacturer's recommended dose. The jars are then loosely capped and placed in a dark box or closet.

Once a month the jars are opened, most of the fuel is removed and replaced with fresh fuel, and the jars are re-treated with their respective additives. This process is repeated until, after 12 to 18 months, the "control" coupon has become well fouled. At that point all jars are compared and scored based on:

1. Fouling of the coupon surfaces

2. Corrosion of the coupon (by weight loss)

3. General growth of sludge (determined by pouring contents through a strainer)

Each jar is scored on a scale of 0-10, with the "control" scoring a "2" in each category. In any category, a score of less than "2" indicates the additive was actually worse than no treatment at all and a score of "10" indicates that additive was perfect in that regard. Below is an example of a typical result:

When using this information, we recommend that you look for products that score high in the categories of interest to you. For instance, if you are interested in less sludge fouling but don't care about whether tanks are corroding, focus on the fouling categories. In general, the product(s) with the higher ratings should be expected to perform better in the field.

The results you see here represent the newest results we have. "Newer" versions of some products are slated for testing in the next few months, and we'll update our results as they become available.

The results you see here represent the newest results we have. "Newer" versions of some products are slated for testing in the next few months, and we'll update our results as they become available.

Contact Us

Fairville Products, Inc

Fuel Right

41 Germay Drive,

Wilmington, DE 19804

Phone: (302) 425-4400

Email: sales@fuelright.com

Web: http://FuelRight.com

Fuel Right

41 Germay Drive,

Wilmington, DE 19804

Phone: (302) 425-4400

Email: sales@fuelright.com

Web: http://FuelRight.com

Add your custom HTML here

Upcoming Events

VISIT US! APRIL 15 - 17

Upper Midwest

Convenience Store & Expo

Upper Midwest

Convenience Store & Expo

Recent Blog Posts

20 Feb, 2024

Spring is almost here , and most fuel dealers agree that this has been one of the more challenging heating seasons in recent memory, with many dealers looking at taking a serious financial hit. But there ’ s a bright spot. An easy way to add an extra $30+ in pure profit per customer to the bottom line – with a premium tank treatment program! Your Customer’s Tank: The Ugly Piece Of Iron That’s A Hidden Profit Center We know tank failure is one of the reasons customers convert from oil to gas. But by offering a premium tank treatment, you not only give your customers peace of mind, but it can allow you to profit in three ways: First, when properly presented, customers will gladly pay for this service every year. Secondly, by choosing the right treatment product, you can also lighten the load next season for your service department. And finally, keeping your customer happy, helps you keep your customer for the long term. Does A Tank Treatment Program Really Make Money? Yes! One dealer introduced such an annual tank treatment program over 20 years ago, and since then, it continues to bring in well over $100,000 net to their bottom line every year as a result. Setting Up Your Own High Profit Tank Treatment Program. STEP 1: Tell Your Customers You’re Now Offering A Premium Tank Treatment Program It can be a flyer, an “on hold ” message, a line item on a service contract, or making sure everyone in your company mentions it to your customers. There ’ s no need to promise specific results or guarantees, just that you are offering this service. STEP 2: Put The Plan Into Action You can start the program at any time, but the best time may be during the off-season. Simply have employees that don’t have a lot to do, visit the customer’s site and pour a bottle of treatment into the tank. You could also have your delivery drivers dispense the treatment during a summer fill. For customers who have annual service contracts you could have the technician deliver the treatment while he’s servicing the customer’s system. That’s it! No guarantees, no insurance, no employee training, and no claims! STEP 3: While You’re At It, Why Not Use A Treatment That Really Works? With the flood of additives on the market (all making a lot of claims) you need to select the best, full spectrum treatment that: (1) Stops sludge related service calls (2) Slows or stops corrosion (3) Cleans the system from “ tank to nozzle ” To see a full analysis & rank of all of the major additives, and to help you select the right product for your tank treatment program, just visit http://FuelRight.com Just How Much Can You Make? It’s Up To You! Price your program to cover the cost of the treatment product, plus the cost of having it applied by your employees, plus add enough profit on top to make you smile when you look at your year end balance sheet! A Win-WIn For You & Your Customer! If you want to add more to your bottom line & retain customer customers, why not consider adding offering a premium tank treatment program. It’s easy to do, helps increase profits and keeps your customers happy. If you have questions or need more information on to start your own tank treatment program, contact us. We’ll be glad to help design a premium tank treatment program that is right for you. Bob Gatchel is the National Sales Director for Fairville Products, Inc. the creator of the Fuel Right® line of fuel & system treatment products. Fuel Right® products have been successfully used for more than 20 years in the fuel oil industry & were voted “Best In The US” against corrosion by the PMAA members.. For more information contact Bob at FuelRight.com or 302-425-4400